滚塑制品的基础生产过程非常简单就是将粉状或浆状高聚物放到模具里加温同时模具紧紧围绕个竖轴转动自转和公转,随后冷却成形的,那麼它具备象征性的运用有什么呢?下边让我们一起来认识下吧。

1、容器类滚塑制品

这类塑料制品普遍用以贮水槽、各类液滚塑态化工品的储槽(如酸、碱、盐、化学农药等) ,气油用器皿(气油储槽及轿车、飞机用油箱) ,电瓶的滚塑油箱罩壳等等。

2、轿车用滚塑制品

主要是运用高压聚乙烯和聚乙滚塑制品烯糊树脂,滚塑各类管件,如空调机弯头、椅背、护栏等。

3、体育器材及各类代用品

主要有高压聚乙烯糊滚塑的各类制品,如水球、浮球、单车坐垫,小帆船以及船和船坞之间的缓冲吸震器等。

4、小玩具、各种工艺品等

因为可以选用精.密浇筑、电铸等工艺制造;滚塑制品表层对模具凹模表层的精细结构”复制”效果非常好,因而滚塑法可以使制品作得非常精美漂亮,故常见于制得具备较:大观赏性的产品,尤其是小玩具、各种工艺品等。

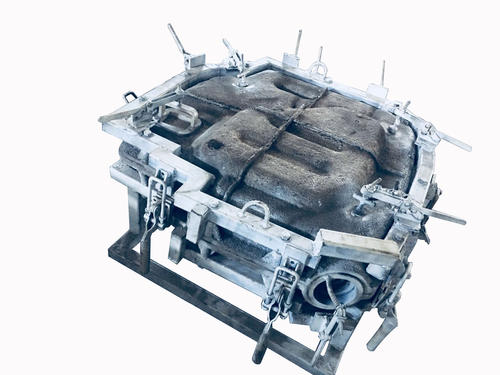

5、除咦上述外,滚塑运用较多的也有各类厢体、壳大型管件等制品,如塑料周转箱、垃圾桶、设备外壳、保护罩、灯盖、浴室、洗手间以及电话间、游船等等。滚塑产品在液态化工品贮运,化工厂、I业喷涂、稀.土制得中的洗槽、反应罐等,也有河海浮标、生活水箱等领域应用已有普遍影响。